Flat Roofing Guide: Materials, Installation, and Cost for Low-Slope Roofs

Owning commercial property or a modern residence means making smart decisions about overhead protection. This detailed resource explains what is flat roofing, investigates what materials can be used for flat roofing, outlines how to install flat roofing correctly, discusses what are the benefits of flat roofing, and clarifies how much does flat roofing installation cost. Extollo Construction developed this guide specifically for property owners who want thorough knowledge about low-slope overhead systems.

What Is Flat Roofing?

Understanding Flat Roof Construction

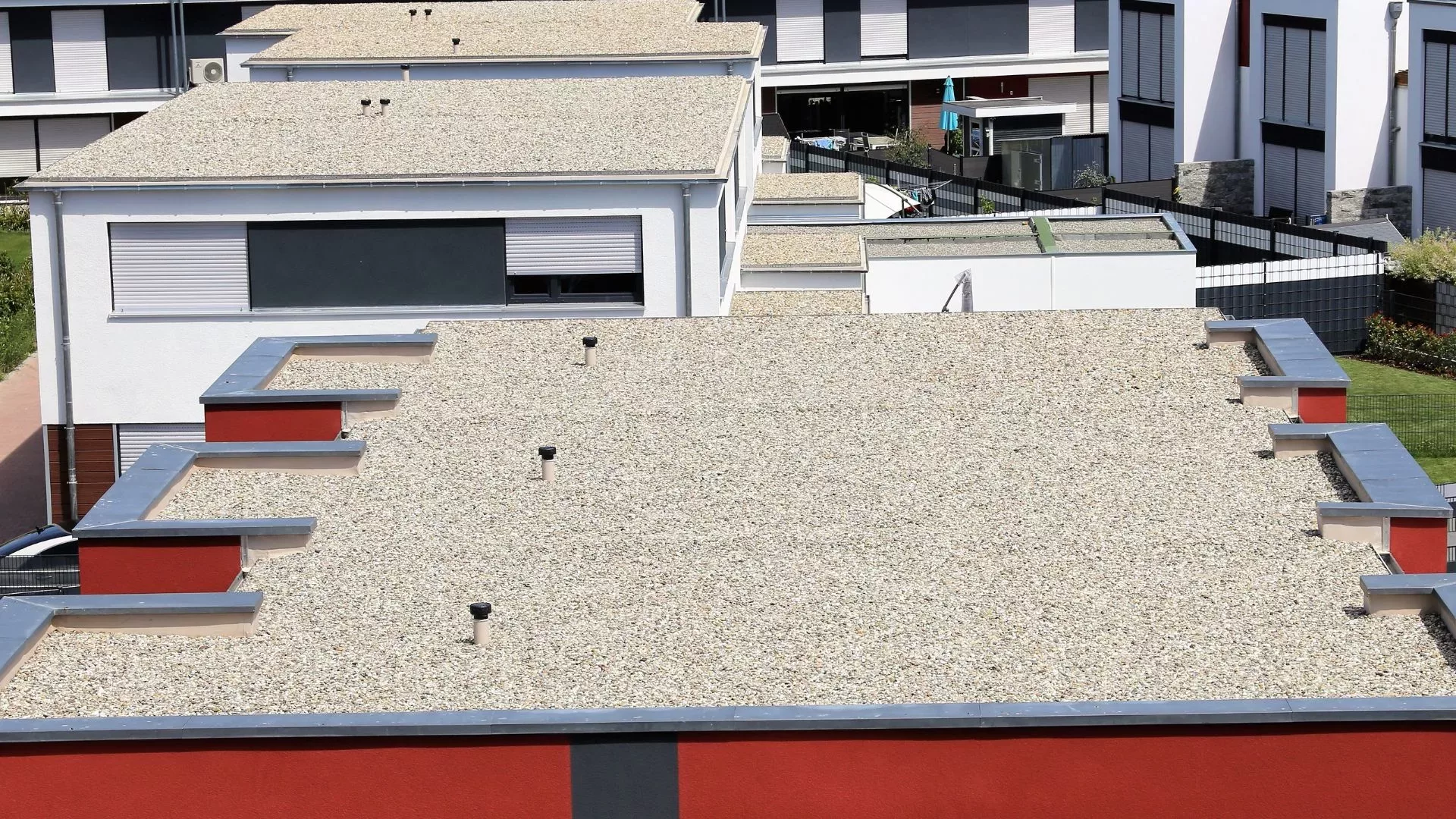

What is flat roofing in practical terms? Contrary to popular belief, these horizontal-looking structures actually incorporate a subtle incline rather than being perfectly level. Specialists classify low-slope configurations as those measuring below 3:12 pitch, while nearly level surfaces maintain just enough grade for proper water movement. Such designs demand specialized products and methodologies distinct from conventional steep-slope approaches.

Where Flat Roofs Are Commonly Used

Commercial properties represent the primary application for these horizontal configurations since they efficiently span large areas. Nevertheless, contemporary residential architecture increasingly features low-slope designs for primary dwellings, room additions, and standalone garages. Modern homes gain aesthetic appeal from the streamlined look, while functional extensions like enclosed porches and vehicle shelters often incorporate similar configurations for harmonious integration.

Flat Roof Components and Layers

A correctly assembled system comprises multiple essential strata functioning in unison. The structural substrate serves as the base, typically constructed from plywood, oriented strand board, or metal decking. Thermal barriers rest above the substrate for temperature regulation, while vapor retarders block moisture migration. The waterproof surface layer provides primary weather defense, and drainage networks guarantee water exits the surface promptly.

Slope Requirements for Flat Roofs

Despite their name, these configurations mandate a minimum gradient of 1/4 inch per linear foot to avoid water pooling. Municipal codes enforce this standard because stagnant water hastens surface breakdown and amplifies structural stress. Contractors establish appropriate pitch through graduated insulation boards or substrate buildup. Sufficient gradient directs water toward collection points, wall openings, or perimeter edges without accumulation.

What Are the Benefits of Flat Roofing?

Cost-Effectiveness and Material Savings

Property owners gravitate toward low-slope configurations because they consume fewer resources than angled alternatives. The diminished surface area directly translates to reduced material expenditures, and straightforward geometry accelerates project completion timelines.

Low-Slope vs. Pitched Structure Cost Comparison:

Material Coverage represents a significant cost difference between the two designs. Low-slope roofs require less square footage of materials due to their minimal angle, while pitched roofs need 20-40% more material to cover the increased surface area created by the steeper angles.

Construction Time is considerably shorter for low-slope designs, typically taking 1-3 days to complete. Pitched roofs require 3-7 days due to the additional complexity of working on angled surfaces, installing more materials, and ensuring proper water drainage on multiple planes.

Labor Complexity varies notably between the two options. Low-slope roofs involve moderate complexity with relatively straightforward installation on near-horizontal surfaces. Pitched roofs present higher complexity, requiring specialized safety equipment, more challenging working conditions on steep angles, and greater technical skill for proper installation.

Initial Investment reflects all these factors in the final cost. Low-slope roofs cost $4-12 per square foot, making them the more economical choice. Pitched roofs range from $7-15 per square foot, with the higher investment attributed to increased material needs, extended labor time, and greater installation complexity. However, pitched roofs often provide better long-term drainage and longer lifespans that may offset the higher upfront costs.

These economic advantages make horizontal designs especially appealing for commercial ventures and cost-conscious homeowners pursuing quality overhead protection without excessive spending.

Additional Usable Space

Horizontal designs convert otherwise unusable overhead areas into practical zones. Elevated decks and terraces generate outdoor living environments in metropolitan settings where ground-level gardens remain scarce. Furthermore, level surfaces support HVAC machinery, photovoltaic arrays, and vegetated garden systems. This adaptability delivers concrete value extending beyond fundamental weather protection, positioning these configurations as wise choices for optimizing property utility.

Easier Access and Maintenance

Service teams and property owners value the accessibility horizontal designs deliver. Technicians traverse the surface safely to examine coverings, unclog drainage, and maintain equipment without requiring specialized harnesses. As a result, periodic assessments cost less and happen more regularly. Restoration work also advances more efficiently because laborers position supplies and implements directly on the working surface instead of navigating steep inclines.

Modern Aesthetic Appeal

Current architectural trends embrace horizontal configurations for their uncluttered, understated visual impact. Architects integrate these profiles to achieve compelling horizontal silhouettes complementing contemporary building aesthetics. Moreover, these designs accommodate parapet barriers that conceal mechanical apparatus while contributing architectural character. The refined appearance attracts property owners pursuing polished, up-to-date design features for commercial and residential structures alike.

Energy Efficiency Potential

Horizontal structures present outstanding prospects for thermal performance enhancement. Light-colored coverings reflect solar energy, cutting cooling expenses by as much as 30% in warm regions. Additionally, the level orientation supports generous insulation depths without the unused space complications typical of peaked attic configurations. These thermal benefits, paired with photovoltaic potential, establish horizontal designs as ecologically sound selections.

What Roofing Material Is Best for a Flat Roof?

Types of Flat Roofing Materials

Current markets present numerous validated choices when evaluating the best roofing options for a flat roof. Property owners frequently ask what roofing material is best for a flat roof, and single-ply products including TPO, EPDM, and PVC lead contemporary projects owing to their resilience and application simplicity. Modified bitumen delivers a crossover solution merging conventional asphalt with advanced polymer science. Built-up assemblies (BUR) persist for scenarios demanding layered redundant protection.

What Is the Best Roofing Material for a Flat Roof?

Determining what is the best roofing material for a flat roof hinges on your particular requirements. TPO provides superb value alongside robust energy performance and chemical resilience. EPDM delivers demonstrated longevity at accessible price points. PVC thrives in chemically demanding settings while offering enhanced fire resistance. Extollo Construction advises assessing your structure's geography, function, and financial parameters to identify the superior choice for your circumstances.

What Materials Can Be Used for Flat Roofing?

Property owners have extensive options when choosing flat roofing materials. Heritage options encompass built-up assemblies and modified bitumen, whereas contemporary single-ply offerings include TPO, EPDM, and PVC. Sprayed polyurethane foam (SPF) delivers gapless coverage incorporating built-in thermal barriers. Metal panels, especially raised-seam configurations, also perform effectively on low-slope applications when contractors employ correct methodologies.

TPO Roofing: Pros and Cons

Thermoplastic polyolefin (TPO) has captured considerable market presence through its equilibrium of performance attributes. This product exhibits outstanding UV tolerance, energy-conscious reflectivity, and puncture and tear resistance. Thermal-welded joints generate watertight connections exceeding the strength of the sheet material itself. Yet TPO compositions differ across manufacturers, with certain earlier formulations experiencing early degradation. Procuring premium products from established distributors remains paramount.

EPDM Rubber Roofing Systems

Ethylene propylene diene monomer (EPDM) has safeguarded low-slope structures for five decades, compiling a remarkable performance history. This synthetic rubber product withstands ultraviolet exposure, atmospheric ozone, and severe temperature variations exceptionally well.

Key EPDM Advantages:

Service duration spanning 25-30 years with appropriate upkeep

Pliability accommodating structural shifting

Offered in 45-mil and 60-mil gauges

Black and white color selections available

Validated effectiveness across every climate region

Techniques encompass fully-bonded, mechanically-secured, and weighted systems, enabling contractors to choose the methodology optimally matched to individual project specifications.

What Is a PVC Flat Roofing System?

What is a PVC flat roofing systems precisely? Polyvinyl chloride products supply remarkable protection against chemicals, petroleum-based substances, and combustion. Food service establishments, industrial plants, and structures featuring rooftop cooking facilities particularly benefit from PVC's immunity to greases and oils that compromise alternative products. Thermal-welded joints form lasting connections, and the product retains pliability across its 20-30 year service duration. Such properties render PVC perfect for challenging commercial settings.

Modified Bitumen Roofing

Modified bitumen merges traditional asphalt with polymer additives to amplify performance qualities. Torch-applied configurations utilize open flames to bond the covering, while peel-and-stick variants eliminate combustion hazards during the procedure. This product yields exceptional waterproofing with recognizable aesthetics and familiar application techniques. Numerous contractors value how modified bitumen successfully bridges heritage and contemporary methodologies.

Built-Up Roofing (BUR)

Built-up assemblies have defended commercial structures for more than a century. Technicians layer bitumen alternately with reinforcing textiles, constructing multiple waterproofing barriers. Aggregate or mineral surfacing shields underlying strata from ultraviolet degradation and mechanical wear. Though labor-demanding, BUR generates overlapping protection appealing to property owners pursuing validated, heritage solutions for their low-slope structural requirements.

Metal Roofing for Flat Applications

Can Metal Roofing Be Installed on Flat Roofs?

Metal panels successfully protect low-slope structures when technicians observe correct protocols. Raised-seam configurations perform optimally at pitches descending to 1/2:12 with suitable seam elevations and sealant compounds. Success depends on blocking water penetration at panel connections since metal lacks the self-healing characteristics of sheet-based systems. Expert execution guarantees these vital particulars receive proper focus for extended performance.

How to Install Metal Roofing on a Flat Roof

Comprehending how to install metal roofing on a flat roof demands focus on multiple pivotal elements. Contractors commence with superior underlayment, frequently fully-bonded covering, supplying backup water defense. Panel work advances from the lower edge upward, applying sealant at every horizontal overlap. Raised-seam fasteners permit thermal expansion while preserving weather-resistant connections. Extollo Construction technicians ensure proper endlap and sidelap sealant application to prevent water intrusion at vulnerable points.

How to Install Corrugated Metal Roofing on a Flat Roof

Mastering how to install corrugated metal roofing on a flat roof introduces distinct obstacles. Corrugated panels demand steeper minimum gradients (generally 3:12 or steeper) than raised-seam options because water can reverse beneath overlaps at shallower pitches. When site parameters allow only minimal gradient, technicians apply abundant sealant ribbons, penetrating fasteners with elastomeric washers, and panel overlaps spanning at least two corrugation waves. Such measures offset the panel profile's constraints.

Standing Seam Metal for Low-Slope Roofs

Raised-seam configurations represent the premier metal selection for low-slope scenarios. Elevated joints measuring 1.5 to 2 inches project above the drainage surface, blocking water from contacting susceptible connection zones. Factory-fabricated panels featuring hidden clips remove exposed fastener penetrations. Furthermore, the interlocking joint architecture manages thermal expansion and contraction. These characteristics unite to produce dependable metal coverings at pitches alternative profiles cannot handle.

Advantages of Metal for Flat Roofs

Metal provides persuasive benefits for suitable low-slope scenarios. Durability surpassing 40-50 years delivers extraordinary value across time. Reflective finishes curtail cooling expenditures substantially in temperate climates. The material completely resists combustion, decomposition, and pest damage. Additionally, metal panels demand minimal upkeep beyond periodic debris clearing. These enduring traits validate the elevated initial expenditure for numerous commercial and residential property owners.

How to Install Flat Roofing

How to Do Flat Roofing: Preparation Steps

Grasping how to do flat roofing commences with comprehensive preparation. Teams examine the substrate for decay, separation, or structural deficiencies demanding remediation. Subsequently, they eliminate debris, protruding hardware, and obstructions that might compromise the fresh covering. Surface cleansing removes particulates and pollutants interfering with bonding. Thorough preparation guarantees the system adheres properly and functions as engineered throughout its anticipated service duration.

Step-by-Step Installation Process

How to install flat roofing adheres to a systematic progression regardless of product selection. Initially, technicians position insulation panels in offset arrangements to prevent thermal conductivity paths. The covering then deploys per manufacturer guidelines for the selected attachment approach. Joint welding or sealing produces watertight linkages between adjacent sheets. Ultimately, teams finalize edge terminations, penetration flashings, and drainage components to conclude the assembly.

Installing TPO and EPDM Membranes

Single-ply covering deployment presents three principal attachment approaches. Fully-bonded configurations cement the sheet directly to the substrate utilizing adhesive compounds, delivering wind resistance without exposed hardware. Mechanically-secured setups employ plates and screws within seam overlaps, providing speed and economy. Weighted configurations position the covering loosely, anchoring it using aggregate or paving units. Each methodology accommodates different structural conditions and budgetary constraints.

Installing PVC Roofing Systems

PVC work necessitates meticulous focus on thermal-welding methodologies for joint integrity. Technicians operate hot-air welding apparatus to merge overlaps into uniform joints.

Critical PVC Steps:

Surface temperature confirmation preceding welding

Uniform travel velocity sustaining appropriate heat delivery

Minimum 1.5-inch joint width attainment

Probe examination of every completed joint

Precision work at penetrations and perimeters

Superior joint welding generates bonds surpassing the parent product's strength. Extollo Construction technicians complete manufacturer certification programs ensuring correct technique execution across every PVC project.

Proper Drainage and Slope Installation

Effective drainage forestalls the most prevalent low-slope structure complications. Graduated insulation assemblies establish positive gradient toward collection points without altering the structural substrate. Engineers compute drainage configurations eliminating accumulation zones and channeling water productively. Technicians confirm gradient achievement before covering deployment using precision instruments and water testing. Such meticulous drainage focus shields the finished system from early deterioration.

Flashing and Penetration Details

Correct flashing execution prevents infiltration at the most susceptible locations. Manufacturers supply prefabricated penetration boots and designated flashing specifications for curbs, vertical surfaces, and perimeters. Technicians apply primer to surfaces before positioning flashing products and verify thorough adhesion without gaps. Joints within flashing zones receive identical welding or sealing treatment as field areas. These termination particulars require careful execution since failures here trigger most water infiltration complaints.

Tools and Materials Required

Expert work necessitates specialized apparatus beyond fundamental hand implements. Thermal welders and hot-air devices manage joint fusion and precision work. Adhesive applicators, spreaders, and spray apparatus distribute bonding agents consistently. Joint probes and thickness instruments confirm quality standards. Moreover, protective equipment encompassing fall arrest systems, appropriate footwear, and personal protective gear safeguards personnel throughout the project duration.

How Much Does Flat Roofing Installation Cost?

Average Flat Roofing Costs by Material

How much does flat roofing installation cost fluctuates considerably based on product selection. EPDM generally spans $4-8 per square foot completed, presenting budget-conscious durability. TPO ranges $5-10 per square foot delivering excellent thermal efficiency value. PVC commands $6-12 per square foot, reflecting its enhanced chemical resistance. Modified bitumen and BUR assemblies occupy the $5-9 bracket, while metal work extends from $8-15 per square foot.

Factors That Affect Flat Roof Installation Costs

Multiple variables shape ultimate project pricing beyond product selection. Structure dimensions influence per-square-foot rates since expansive projects realize scale economies. Existing covering extraction appends $1-3 per square foot to expenditures. Insulation depth specifications directly affect material outlays. Structure elevation and accessibility challenges influence labor expenses. Intricate configurations featuring numerous penetrations, tiered levels, or atypical layouts demand supplementary time and resources.

Labor Costs and Installation Time

Skilled labor customarily constitutes 40-60% of aggregate project expenditures. Seasoned teams accomplish most residential low-slope structures within 1-3 days, whereas commercial undertakings may span 1-2 weeks. Labor charges fluctuate regionally, with urban centers commanding elevated pricing. Contractor standing and craftsmanship caliber rationalize quote disparities. Committing to proficient work safeguards your material investment while averting expensive return visits.

Tear-Off vs Overlay Installation Costs

Applying over existing coverings conserves the $1-3 per square foot extraction expense yet introduces meaningful deliberations. Municipal codes typically cap systems at dual layers maximum. Overlays conceal pre-existing deterioration that persists worsening beneath fresh products. Furthermore, warranty provisions may exclude overlay scenarios. Comprehensive extraction permits substrate examination and remediation while furnishing pristine surfaces for optimal fresh product adhesion.

Long-Term Cost Considerations

Initial project expense constitutes merely a fraction of aggregate investment. EPDM's 25-30 year service duration distributes expenditures productively across time. PVC's chemical immunity eliminates premature replacement in demanding settings. Metal's 50-year resilience furnishes extraordinary extended value notwithstanding elevated upfront costs. Reflective coverings diminish continuous energy expenditures throughout their operational lifespan. Extollo Construction helps clients analyze lifetime costs, which often reveals different value rankings than initial price comparison suggests.

ROI and Value of Quality Installation

Premium work protected by manufacturer guarantees yields quantifiable returns. Extended craftsmanship warranties from certified contractors defend against workmanship deficiencies for 5-10 years. Product warranties spanning 15-30 years address material failures. Collectively, this protection conserves your investment while curtailing extended maintenance outlays. Property valuations similarly benefit from expertly completed systems featuring documented warranty coverage.

Flat Roof Maintenance and Care

Routine Inspection Schedule

Consistent assessments identify minor complications before they escalate into expensive restorations. Arrange comprehensive examinations each spring and autumn at minimum. Scrutinize surfaces for bubbling, fracturing, or perforations. Review joints for separation or curling margins. Confirm flashings remain firmly anchored at every termination. Remove debris accumulations trapping moisture or compromising surfaces. Record observations and resolve issues without delay.

Drainage System Maintenance

Obstructed drainage generates accumulating water that hastens surface breakdown. Extract leaves, sediment, and particulates from collection points, wall openings, and channels consistently. Confirm drain screens remain positioned and intact. Verify downspouts discharge unobstructed. Following substantial weather events, examine the complete drainage pathway for obstructions. Preserving unimpeded drainage protects your investment while preventing structural complications from water mass.

Common Flat Roof Problems

Recognizing prevalent complications helps property owners spot issues promptly. Pooling water persisting 48 hours post-precipitation signals drainage deficiencies demanding correction. Bubbling stems from entrapped moisture or adhesion breakdown beneath coverings. Surface perforations from pedestrian traffic, debris impact, or equipment damage necessitate prompt patching. Flashing breakdowns at penetrations and perimeters trigger most water infiltration grievances. Resolving these complications swiftly forestalls widespread damage.

Preventive Maintenance Best Practices

Forward-thinking upkeep prolongs system longevity meaningfully while diminishing restoration expenditures. Formulate documented maintenance protocols and observe them reliably.

Essential Maintenance Actions:

Prune encroaching tree limbs depositing debris

Position protective walkways in heavy-traffic zones

Administer UV protective treatments to EPDM surfaces periodically

Re-seal exposed hardware heads and flashing perimeters

Chronicle every examination and restoration performed

Collaborating with Extollo Construction for yearly upkeep guarantees professional evaluation and punctual response to emerging concerns.

When to Schedule Professional Inspections

Beyond standard owner examinations, specialist evaluations supply expert analysis. Arrange professional assessments yearly, preferably preceding winter conditions. Request examination following severe weather occurrences including hailstorms, powerful winds, or substantial snowfall. Commission assessment prior to acquiring property featuring low-slope structures. Specialist examiners detect concerns imperceptible to inexperienced observers and deliver precise restoration or replacement guidance.

Flat Roof Drainage Solutions

Why Proper Drainage Is Critical

Stagnant water on horizontal structures triggers numerous grave complications. Supplementary mass stresses structural elements beyond engineered thresholds. Persistent moisture expedites surface deterioration and abbreviates operational lifespan. Pooling zones cultivate algae and plant growth damaging coverings. Freeze-thaw patterns inflict ice damage in frigid climates. Productive drainage abolishes these hazards while defending your investment.

Internal Drains vs Scuppers

Two principal drainage methodologies serve horizontal applications successfully. Interior drains interface with building plumbing networks, evacuating water through the structure. Wall penetrations discharge water externally to channels or grade level. Interior drains perform effectively for expansive structures yet demand maintenance accessibility. Wall penetrations offer simpler upkeep but may inadequately manage extreme precipitation volumes.

Tapered Insulation Systems

Graduated insulation generates positive drainage gradient without structural alterations. Manufacturers fabricate insulation boards incorporating built-in pitch, characteristically 1/8 or 1/4 per linear foot. Engineers devise configurations channeling water toward collection points productively. This methodology appends minimal expense while resolving drainage obstacles on otherwise level substrates. Graduated assemblies merge flawlessly with conventional covering deployment protocols.

Solving Ponding Water Issues

Pre-existing accumulation complications demand focused remedies grounded in causation identification. Minor accumulation frequently responds to supplementary drain positioning or wall opening expansion. Isolated depressions benefit from graduated insulation overlays or self-leveling compounds. Structural sagging causing accumulation may necessitate engineering evaluation and substrate reinforcement. Professional assessment determines the most economical methodology for each particular accumulation circumstance.

Flat Roof Insulation and Energy Efficiency

Insulation Options for Flat Roofs

Horizontal structures accommodate multiple effective thermal barrier products. Polyisocyanurate (polyiso) supplies the supreme R-value per inch, rendering it favored where depth matters. Expanded polystyrene (EPS) furnishes economical thermal effectiveness with outstanding moisture immunity. Extruded polystyrene (XPS) provides uniform performance in below-surface scenarios. Sprayed polyurethane foam generates gapless thermal barriers with incorporated air-sealing characteristics. Product determination depends on climate, finances, and deployment methodology.

R-Value Requirements and Building Codes

Municipal codes define minimum insulation specifications varying by climate region and structure classification. Present energy standards mandate R-25 to R-35 for most commercial horizontal applications. Residential specifications typically equal or surpass commercial benchmarks. Code adherence verification transpires during permit assessment and examination procedures. Surpassing minimum standards frequently proves financially sensible considering energy savings across the system's operational duration.

Cool Roof Technology

Reflective coverings redirect solar energy instead of conducting warmth into structures. White or pale-tinted TPO and PVC offerings attain solar reflectance indices (SRI) exceeding 100. Such reflectivity diminishes surface temperatures by 50-70°F versus dark-colored coverings. Reduced surface temperatures decrease conditioning loads and prolong product longevity. Numerous jurisdictions extend incentives for reflective assemblies satisfying designated performance benchmarks.

Green Roof and Solar Panel Integration

Horizontal structures distinctively support sustainable construction technologies. Vegetated assemblies stratify growing medium and flora over waterproof coverings, delivering thermal performance, stormwater control, and metropolitan ecosystem benefits. Photovoltaic arrays mount productively on level surfaces featuring optimal angle calibration. Certain projects merge vegetated systems with solar arrays for maximum advantage. Such applications supplement value while advancing ecological stewardship objectives.

Commercial vs Residential Flat Roofing

Commercial Flat Roof Systems

Commercial horizontal structures confront demands surpassing residential scenarios. Expanded spans necessitate careful consideration of covering stress and thermal dynamics. Rooftop climate-control equipment concentrates loads while generating penetration obstacles. Pedestrian traffic from service staff requires resilient surfaces and protective walkways. Municipal codes mandate stricter combustion resistance and wind resistance specifications. Extollo Construction contributes specialized proficiency to these demanding commercial scenarios.

Residential Flat Roof Considerations

Residential horizontal structures introduce distinct priorities versus commercial endeavors. Visual harmony with dwelling architecture shapes product and color determination. Reduced scale permits expanded product alternatives and deployment methodologies. Homeowners frequently prefer accessible overhead spaces necessitating suitable product determination. Moreover, residential scenarios may authorize owner-performed upkeep that commercial properties prohibit. Comprehending such distinctions steers suitable system determination.

Code Requirements by Application

Municipal codes distinguish specifications grounded in occupancy classification and structure dimensions. Commercial structures encounter stricter combustion resistance designations, frequently mandating Class A certified assemblies. Wind resistance testing must exhibit performance satisfying local engineering specifications. Thermal values conform to commercial energy code computations differing from residential benchmarks. Permit prerequisites and examination protocols similarly diverge by scenario classification and jurisdiction.

Professional Flat Roofing Services

Why Choose Professional Flat Roof Installation

Expert execution guarantees correct completion of pivotal particulars determining system effectiveness. Certified technicians comprehend gradient specifications, drainage engineering, and covering deployment methodologies. They command apparatus for correct joint welding and verification. Manufacturer accreditation confirms warranty legitimacy and appropriate product handling. Professional teams operate securely and productively while safeguarding your property throughout project duration.

Free Flat Roof Inspection and Estimate

Comprehending your structure's present state steers suitable decision-making. Thorough examinations pinpoint pre-existing deterioration, drainage deficiencies, and residual operational duration. Itemized quotations decompose product alternatives, methodologies, and anticipated expenditures transparently. Such intelligence empowers educated selections regarding restoration versus replacement and product determination. Reach out to arrange your complimentary evaluation and consultation.

Our Flat Roofing Installation Process

Extollo Construction observes a methodical protocol guaranteeing uniform quality outcomes. Undertakings commence with exhaustive site evaluation and product designation. Teams ready surfaces scrupulously before positioning thermal barriers and coverings. Joint welding and flashing particulars receive painstaking execution and verification. Concluding examination confirms adherence to manufacturer specifications and our quality benchmarks. Documentation and warranty materials finalize the professional deliverable.

Emergency Flat Roof Repair Services

Water infiltration demands swift reaction to avert interior damage and operational interruption. Our emergency assistance furnishes immediate evaluation and provisional waterproofing when instantaneous permanent restoration proves impractical. Technicians arrive outfitted to manage prevalent emergency circumstances productively. Subsequent permanent restorations tackle underlying causes instead of mere symptoms. Such responsive assistance shields your property pending comprehensive solution deployment.

Comprehensive Flat Roof Solutions

Complete assistance spans every dimension of horizontal structure stewardship. Fresh construction undertakings showcase premium products and masterful craftsmanship. Rehabilitation and protective coating assemblies prolong existing system longevity economically. Upkeep programs deliver scheduled examinations and anticipatory attention. Restoration assistance resolves complications promptly before escalation. Such comprehensive methodology sustains your requirements throughout the system's complete operational cycle.